WFG - next generation of thread whirling

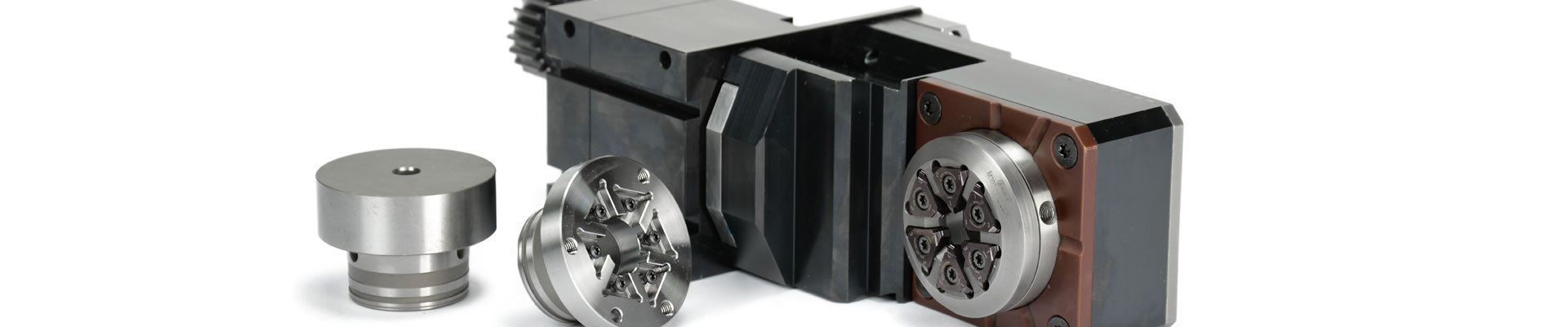

In times of rising machine cost, it is important not only to increase productivity by means of new materials and production processes, but also to minimize machine downtimes. To help you achieve this goal, we have developed innovative modular thread loom units from W&F, which are equipped with our patented high-precision interface "WFG".

The installation and removal of the thread whirl as well as the associated alignment is a thing of the past thanks to the use of modular thread whirling units. Due to the high concentricity of the interface and the even wear of the cutting plates, a lifetime increase of up to 300% can be achieved.

- changing of the insert: < 1 min

- runout accurancy: < 3µ

- repeatability: < 2µ

- presetable outside of the machine

- available for common swiss-type machines

Through the interplay of cone-shaped shell and planned assets with cylindrical support, we not only reach highest preciseness in the interface it self, but also an user-friendly changing of the inserts with only three screws.

Our “blanks-principle“ enables highest flexibility and the opportunity to use your needed respectively your preferred insert tips. The according insert seats can be made by the manufacturer of the insert tips, or by your self as well.